Products

- View as

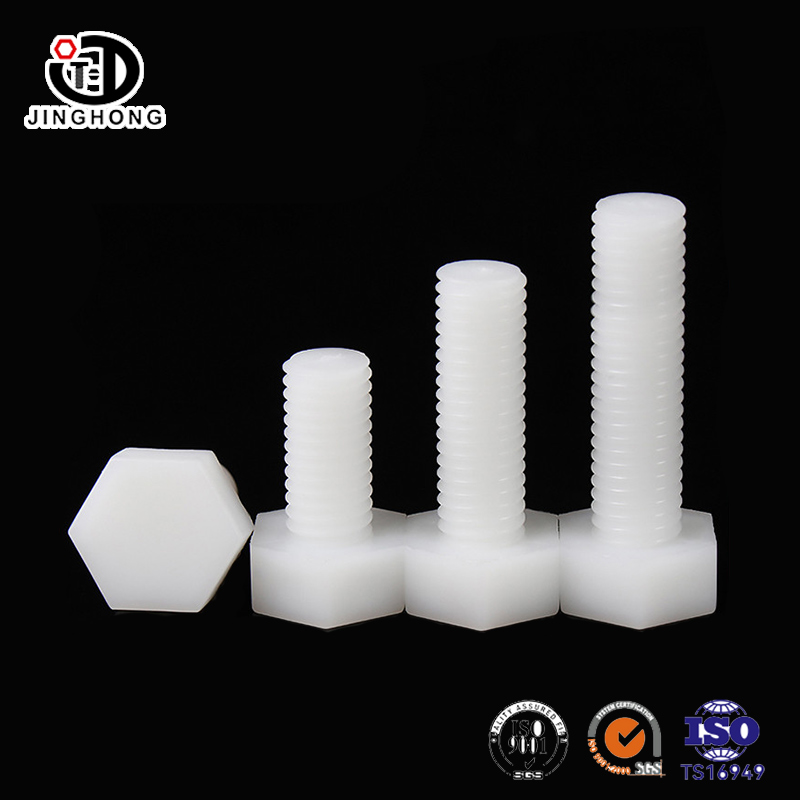

White Nylon Hex Head Screw

Nylon hex head screw is the fastener that is composed of nylon material and has hex head. With the help of the characteristic of nylon, it is very light, anti-corrosion, electric insulation and somewhat flexible. It is largely applied in electronics, appliances, toys, furniture and other hundreds of industries-where you need insulation, anti-corrosion or lighten-weight. Compared with metal screw, nylon hex head screw is easier to screw in and can avoid the galvanic current that will be generated by the two different metals contacting each other.

Read MoreSend InquiryFlat Head Iron Rivet

The flat head iron rivet is a type of rivet, and is typically made of iron. The top is flat and round, and the rest of the body is cylindrical. It is simple and convenient. If we use it to rivet, it can be used to fix two or more materials together. Flat head iron rivets are commonly used in building , automobile and machinery manufacturing. They are treated to prevent rust, so they can be used in various situations. They are very important to maintain the stability of buildings.

Read MoreSend InquirySemi-Round Head Solid Iron Rivet

Semi round head solid iron rivet is a kind of common metal fastening parts. Its head is dome and its stem is solid usually made of iron, because iron is very solid. It is widely used in machinery manufacturing, building, vehicle manufacturing and other parts connection. Because of the dome head, the stress will be evenly and strongly dispersed, so the connection between two parts is very stable.

Read MoreSend InquiryStainless Steel Ball Plunger Set Screw

Stainless steel Ball Plunger Set Screw are fine screws with a spring-loaded ball at the end which makes them easy to set and fasten.Smooth surface and clean threads. They are made from the highest quality stainless steel and have good corrosion resistance and strength. These are used in machinery that needs to be adjusted frequently or requires a specific alignment.

Read MoreSend InquiryZinc-plated Hexagonal Head Self-tapping Screw

Zinc plated hex head self tapping screw. With hex head for easy driving with tools. Self tapping means this screw can made its own thread as it is driven down into material. So easy to screw in. The zinc plating provides good resistance to rust and extends the life of the screw. Used in building, furniture, wood joinery and many other applications

Read MoreSend Inquiry