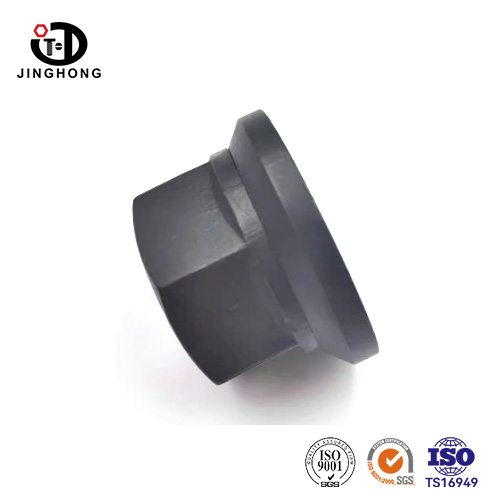

Wheel Flange Nut

The material used for Wheel Flange Nuts is typically chosen for its strength, durability, and resistance to environmental factors, such as corrosion.The nut features a flat and wider base (flange) that provides a larger surface area for contact with the wheel. This design enhances stability and helps distribute the load.

Send Inquiry

Jinghong fasteners has 20years more experience,if you need which one and what kind of material ,it’s up to your demand.If you have more specific questions or need more information you can contact us without any doubt.

| Name | Wheel Flange Nut |

| Material | Carbon steel/Steel/Alloy steel/Stainless Steel/Brass |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

| Sizes | M18-M22 Metc |

| Finish | Steel /others |

| Price | 0.04usd/pcs-0.50usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

The hex size of the wheel flange nut corresponds to the size of the wrench or socket needed for installation.Constructed from durable materials like steel or alloy to withstand the forces and stresses encountered during vehicle operation.Available in various thread sizes to match the specific requirements of different vehicles.May have coatings or finishes such as zinc or chrome to improve corrosion resistance and enhance appearance.Features a conical seat design that matches the angle of the wheel's lug holes, ensuring a secure fit.It's crucial to ensure that the wheel flange nut is compatible with the vehicle's wheel and hub specifications.The flanged design aids in distributing the load evenly, reducing stress on the wheel and ensuring a secure connection.Materials and coatings are chosen to resist corrosion, providing longevity and reliability in various environmental conditions.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.