Stainless Steel Spring Ball Plunger

Stainless Steel Spring Ball Plunger is a precision fastener that combines precise positioning and elastic locking functions. It achieves seamless positioning, elastic buffering, and anti vibration loosening through the contact between the hardened steel ball pushed by the built-in spring and the groove or plane of the mating part. The all stainless steel material provides excellent rust and corrosion resistance.

Send Inquiry

Do you need to ensure that two components can be quickly and accurately aligned during design or assembly, while also having a certain degree of "elasticity" to avoid rigid collisions or compensate for minor errors? Or in high-speed vibration equipment, ordinary fastening screws are prone to loosening, affecting positioning accuracy?

This Stainless Steel Spring Ball Plunger is designed to address the pain points of such projects. Its core is a sophisticated built-in spring and hardened stainless steel beads. After the screw is screwed in, the protruding steel ball continuously and stably presses against the matching components under the pressure of the spring.

Jinghong focuses on fastener manufacturing with high quality alloy steel and stainless steel. We use precise cold-heading forming process and surface passivation process for our products. They can work well in extreme environment. We offer total solutions from common fasteners to customized fastener. There are certain ranges that can be adjusted for thread parameter and component form. The products are used in wide range of industries from consumer goods to large industrial machines.

| Name | Stainless Steel Spring Ball Plunger |

| Material | Stainless Steel |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

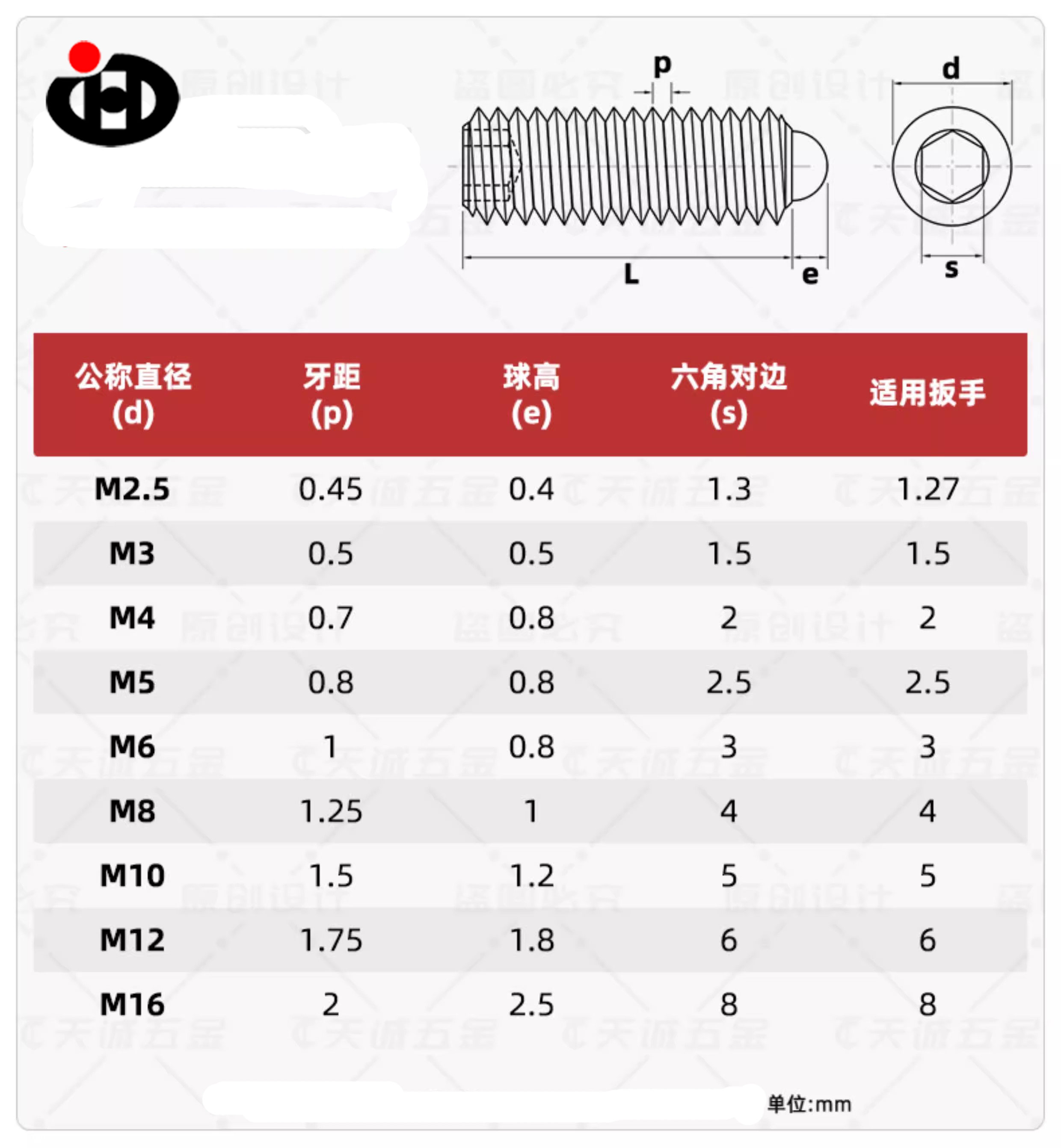

| Sizes | M2.5-M16 |

| Finish | Plain/Black/others |

| Price | 0.04usd/pcs-0.50usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

Accurate positioning: Through the cooperation of steel balls and positioning grooves, the components can be quickly and accurately positioned at angles or axial directions.

Elastic pre tightening: The spring provides constant pressure, eliminates assembly gaps between components, prevents shaking, and can absorb small vibrations and thermal expansion and contraction.

Convenient operation: With a standard hex wrench, pressure can be easily adjusted or disassembled, making it a reusable functional component.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Patent certificate

Production workershop

Production workshop

Production workshop

Production workshop

Production workshop

CNC workshop

CNC workshop

Testing Office

Testing Office

Finished product workshop

Finished product workshop

Loading and transportation

Loading and transportation

Partners visit the factory