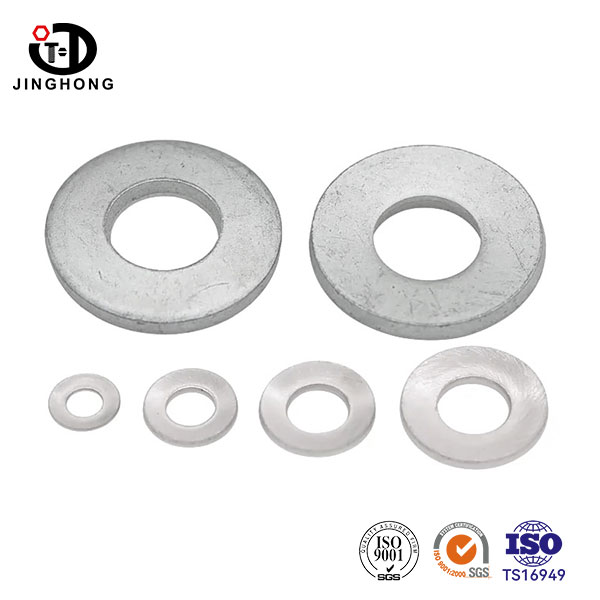

C67 Carbon Steel Shaft Retaining Ring

The C67 carbon steel shaft retaining ring is a shaft retaining ring made of C67 carbon spring steel, providing high elasticity and fatigue resistance. Suitable for axial positioning and fixation of components such as bearings and gears, with precise dimensions and stable installation, it is a key standard component in mechanical equipment.

Send Inquiry

In many rotating mechanical devices, such as motors, gearboxes, and rotating shafts, there is a common challenge: how to reliably fix bearings, gears, or washers to prevent them from axial play on the shaft? Welding is not practical, and nuts take up too much space.

The C67 carbon steel shaft retaining ring from Jinghong manufacturer is a classic and efficient solution to this problem. The shaft retaining ring is an open elastic ring with an inner diameter slightly smaller than the diameter of the shaft. During installation, it is stretched open using specialized snap pliers and inserted into the pre machined rectangular groove on the shaft. With the excellent elasticity of C67 material, the retaining ring will quickly shrink and firmly clamp in the groove, forming a sturdy annular shoulder that precisely limits the axial movement of other parts.

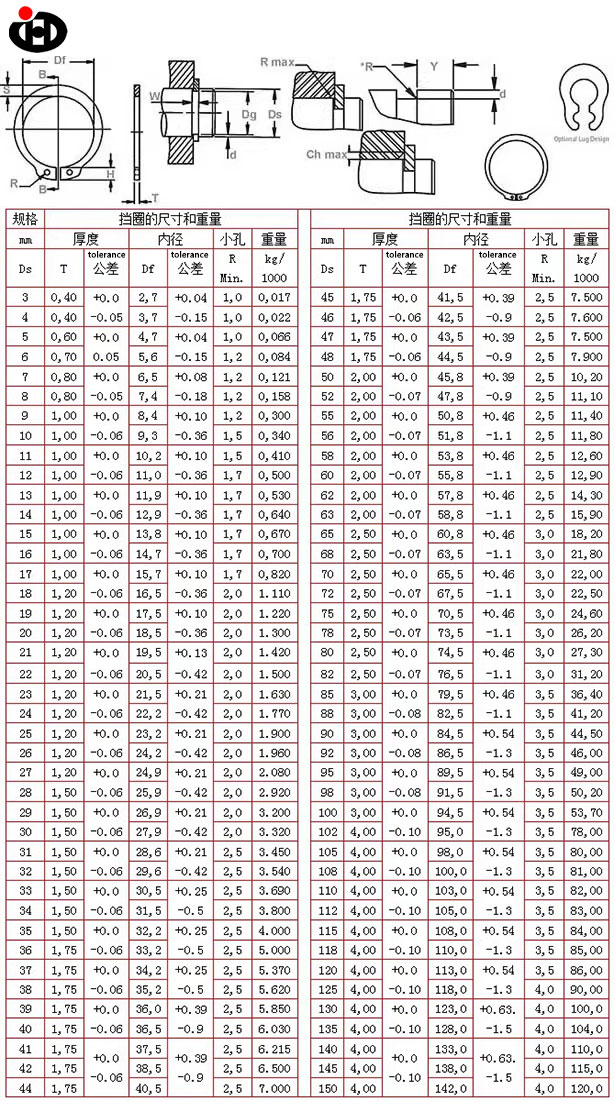

| Name | C67 Carbon Steel Shaft Retaining Ring |

| Material | Carbon Steel |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

| Sizes | M3-M150Metc |

| Finish | Plain/Black/Zinc plated/Other |

| Price | 0.03usd/pcs-0.50usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

C67 carbon spring steel: This is the cornerstone of retaining ring performance. After quenching and tempering treatment, this material has high elastic limit and excellent anti relaxation ability, ensuring that the retaining ring can maintain sufficient clamping force after long-term use and will not fail due to "elastic attenuation".

Strong fatigue resistance: able to withstand repeated impacts and vibrations caused by equipment start stop and load changes, it is a reliable choice in dynamic application scenarios.

Surface treatment options: The standard is blackening treatment, providing basic rust prevention and aesthetic appearance. Galvanization can also be carried out according to requirements to enhance corrosion resistance in humid environments.

Deburring process: All retaining rings undergo fine deburring treatment, with smooth edges to avoid scratching the operator's fingers or the surface of the shaft during installation.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.